3D Surveys in Explosive Environments and ATEX Zones

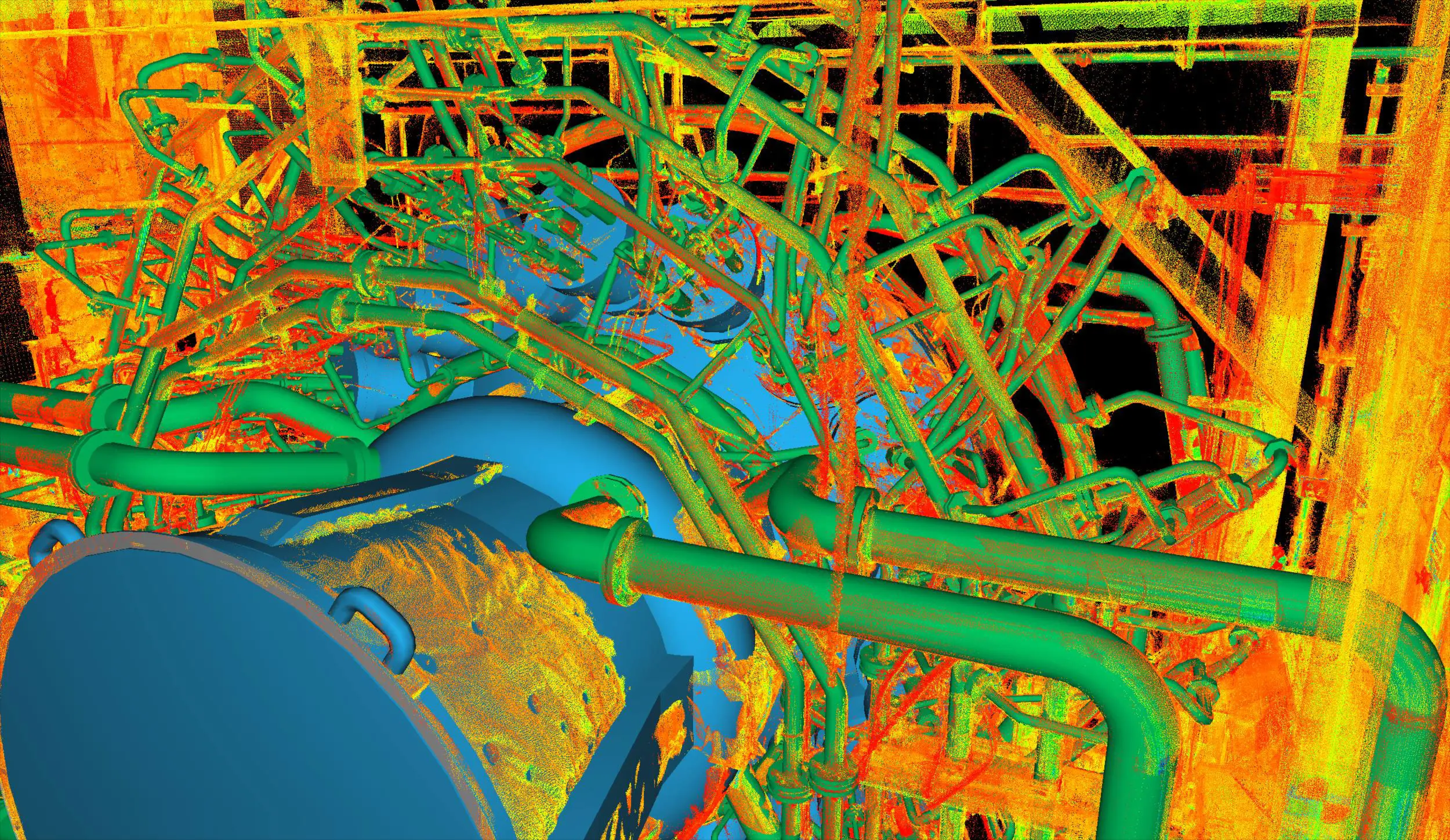

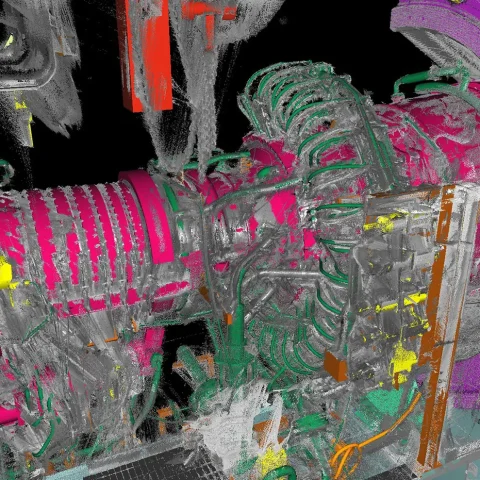

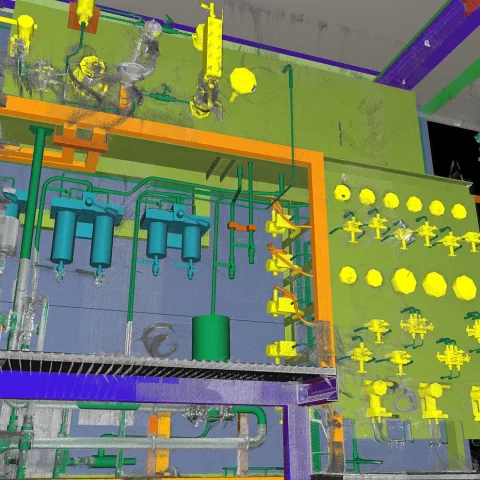

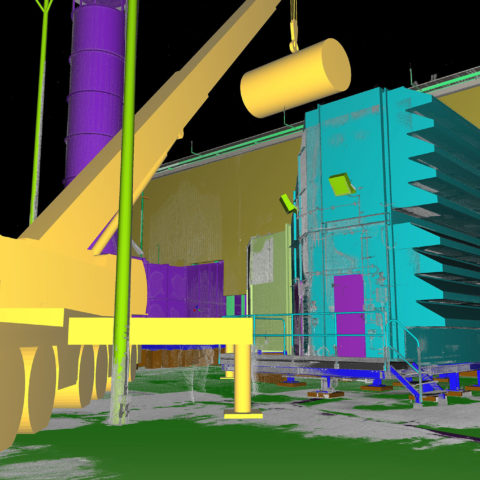

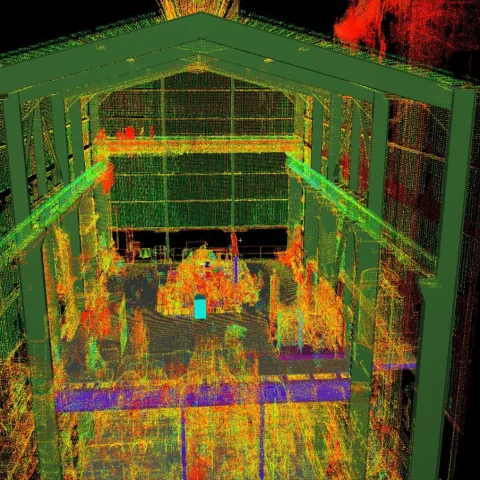

GaiaGroup introduces a highly specialized service for 3D surveying in ATEX-classified environments — areas with potentially explosive atmospheres where most traditional equipment cannot operate safely. Thanks to the use of the Z+F IMAGER® 5006EXscanner — one of the very few ATEX-certified instruments in the world — we are able to acquire high-precision 3D data even in restricted-access or high-risk areas such as refineries, chemical plants, industrial storage facilities, or mines.

This exclusive service, made possible by state-of-the-art equipment and a highly qualified technical team, allows surveys to be carried out in complete safety — reducing plant downtime, increasing data reliability, and ensuring compliance with current regulations.

WithGaiaGroup, technology, safety, and precision come together to deliver a tailored solution for the needs of the most demanding industries.

Key Features of the Z+F IMAGER® 5006EX

- ATEX Certification: Suitable for Zones 1 and 2 (gas) and Category M2 (mines), compliant with Directive 94/9/EG.

- Extended Field of View: 310° vertical and 360° horizontal coverage, allowing comprehensive documentation with minimal scan positions.

- High Acquisition Speed: Up to 508,000 points per second, with an ambiguity interval of up to 79 meters.

- Millimetric Precision: Linearity error up to 1 mm over 50 meters, with a measurement noise of 0.7 mm RMS.

- Stand-Alone Operation: Internal battery replaceable in explosive environments, with control via integrated display or Wi-Fi connection.

Service Applications

Thanks to the use of the ATEX-certified Z+F IMAGER® 5006EX scanner, GaiaGroup is able to provide safe, fast, and accurate 3D surveys in a wide range of high-explosive-risk environments, where laser scanning would normally be impossible or severely restricted.

The main applications include:

- “As-built” surveys in complex industrial plants, where it is necessary to document the current state of structures, pipelines, and components for maintenance, revamping, or design purposes.

- Mapping of confined and hazardous environments — such as tanks, tunnels, storage areas, silos, or chemical plants — with limited access and the presence of potentially explosive gases or dust.

- Technical inspections and non-destructive testing, ideal for assessing the condition of structures without interrupting plant operations.

- Documentation of mining areas or underground sites, where the lack of ventilation and the presence of volatile substances require the use of ATEX-certified equipment.

- Deformation or time-based comparative monitoring, useful for assessing structural movements, settlements, subsidence, or even minimal dimensional changes.

- Pre- and post-intervention surveys for work validation, to be included in testing procedures, certifications, or safety plans.

All acquired data can be processed into 3D models, cross-sections, orthophotos, and point clouds compatible with the most common design and BIM software.

Why Choose GaiaGroup

Choosing GaiaGroup for 3D surveys in ATEX environments means relying on a partner with proven experience, cutting-edge technology, and full regulatory compliance. We offer a complete service — from project planning to the delivery of processed data.

Here’s what sets us apart:

- Certified expertise: Our technical team is trained to operate in ATEX risk environments, following strict safety protocols and undergoing continuous updates.

- Safety first: Every operation is carried out in compliance with European ATEX regulations and using certified equipment for hazardous areas (Zones 1, 2, and Category M2).

- Data Reliability: The laser scanner used enables millimetric-precision surveys, minimizing margins of error and the need for design rework.

- Tailored solutions: We provide both one-off interventions and complex projects with multi-site management and integration into CAD/BIM environments.

- Operational flexibility: Option to request equipment rental with an operator, ideal for temporary needs or urgent interventions.

- A single point of contact: No intermediaries — GaiaGroup directly handles the equipment provision, technical inspection, and survey execution.

With GaiaGroup, every project is approached with technical precision, a comprehensive vision, and meticulous attention to detail.

Service Also Available for Rental with Operator

Do you need the Z+F IMAGER® 5006EX scanner for a specific task but prefer not to invest in purchasing the equipment?

With GaiaGroup, you can rent the equipment along with a specialized operator, ensuring:

- Operational safety in ATEX environments

- Maximum efficiency in acquisition times

- Zero technical complications: we take care of everything

Contact us for a personalized quote and discover the flexible solutions designed for companies and industry professionals.